|

|

Onsala Space Observatory Group for Advanced Receiver Development

|

|

Welcome to GARD OSO ALMA Band 5 Project Web-pages

ALMA Band 5 Cartridge Development

Contributors

V. Belitsky, I. Lapkin, B. Billade, E. Sundin, A. Pavolotsky, D. Meledin, M. Strandberg, , O. Nyström, V. Desmaris, M. Fredrixon, D. Dochev, S.-E. Ferm – all are with the Group for Advanced Receiver Development (GARD), Department of Radio and Space Science and Onsala Space Observatory, Chalmers University of Technology, SE 412 96, Gothenburg, Sweden. D. Henke is currently with the NRC Herzberg Institute of Astrophysics, (NRC-HIA), 5071 West Saanich Road, Victoria, British Columbia, Canada V9E 2E7. R. Finger is with the Departamento de Astronomía, Universidad de Chile, Casilla 36-D, Santiago, Chile.

Disclaimer: this page is for information purpose only. Actual performance and design of the ALMA Band 5 Cartridge shipped to ALMA European Integration Center is presented in the documentation package and can be accessed through ALMA Documentation Server (requires login).

INTRODUCTION

The ALMA Band 5 is an EC Framework Program 6 (FP6) infrastructure enhancement project aiming at the development and design of a prototype receiver cartridge fulfilling specifications of ALMA Band 5. After the prototype cartridge is accepted, the project considers to supply 6 production cartridges for the ALMA Project for integration into the ALMA frontend receiver. Group for Advanced Receiver Development, OSO, Chalmers University, is responsible for cold cartridge assembly (CCA). STFC Rutherford Appleton Laboratory, UK, are our partners in the ALMA Band 5 project and responsible for development of the Band 5 warm cartridge assembly (WCA) and the local oscillator (LO) sources.

The Band 5 cartridge is a dual ‑ polarization receiver with the polarization separation performed via orthomode transducer (OMT) [1]. The receiver is based on sideband rejection quadrature layout (2SB) and employs modular design with SIS DSB waveguide mixers, covering 163-211 GHz with 4 ‑ 8 GHz intermediate frequency (IF) band.

The ALMA Band 5 cartridge is the lowest frequency channel of the ALMA frontend that utilizes all ‑ cold optics and thus has the largest mirrors amongst the other ALMA bands with cold optics. The Band 5 optics mirrors together with its support structure leave very little room for placing the receiver components, such as the corrugated horn, OMT, the mixers for both polarizations and the IF system and thus calling for specific technical and design solutions for the layout of the cartridge.

OPTICS DESIGN

Band 5 mirrors and corrugated horn formal parameters are based on the design proposed by M. Carter, et al. [2] and has been analyzed by M. Whale, et al. [3] through physical optics simulations to ensure no unwanted cross‑polarization components added and overall efficiency is within specs.

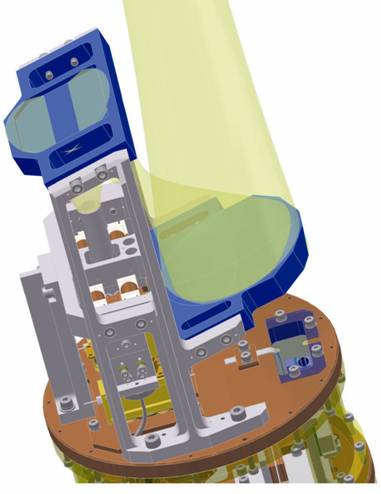

In order to make the cold optics structure stiff and yet easier to manufacture, the Band 5 optical support was designed integrated out off several parts rather than machined as a single piece. The optics mounted on the 4K plate of the cartridge includes the support brackets, two at the sides and one central, the crossbar for mixer assembly interfacing and two mirrors, all made off aluminum alloy, Fig. 1.

|

|

|

Fig. 1. Band 5 optics integrated. The two mirrors are supported by two vertical brackets with the crossbar providing reference plane, cooling and support for the mixer assembly integrated around the OMT. Additional vertical support bracket (not shown) provides supplementary cooling and adds stiffness to the main support brackets.

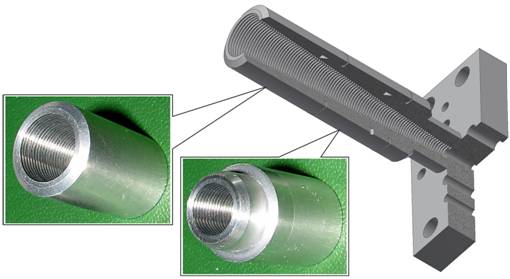

The corrugated horn is directly attached to the crossbar connecting the vertical optics support brackets and providing a mechanical interface to the mixer assembly. The corrugated horn has 94 corrugations (Fig. 2) and has been designed using an optimization procedure that simultaneously aims to the best Gaussian fit of the main lobe while minimizing the side-lobs below -30 dB level, Fig 2.

Fig. 2. ALMA Band 5 corrugated horn. The horn is made of aluminum and consists of 3 parts connected via press-fit joints. The split was made to facilitate machining.

MIXER ASSEMBLY

As discussed in the introductory part, the cold mirrors of the ALMA Band 5 cartridge with the specified mirror rim size of five beam waists (5wo) are large, as compared to other ALMA bands, because of it relatively low operating frequencies. The space available for placing the mixer assembly is next to the Mirror 1 (M1), Fig. 1. In order to fit this room, the polarizations should be split by an OMT and directed towards opposite sides in parallel behind M1.

|

|

|

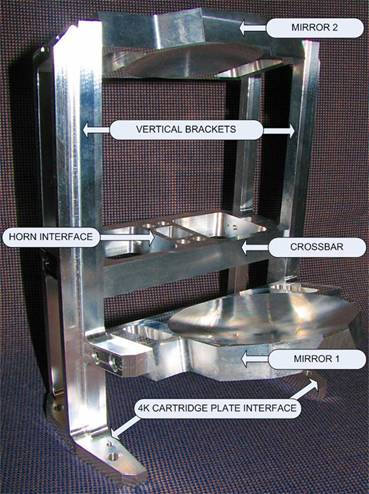

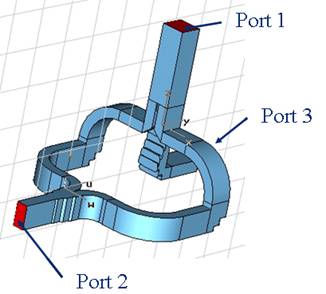

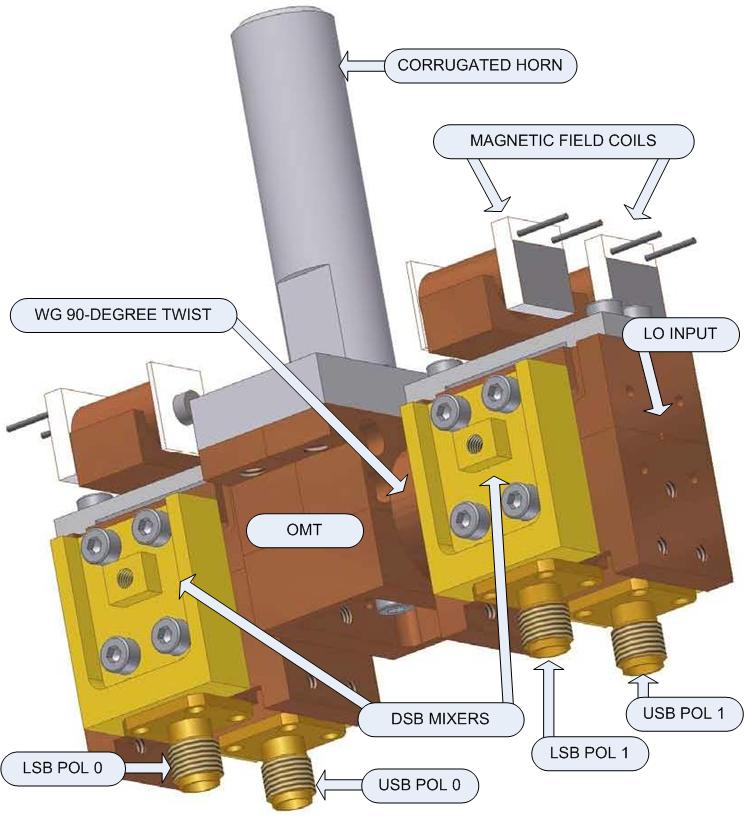

Fig. 3. Band 5 cartridge OMT [1] with input via square waveguide (port 1) and outputs (port 2 and 3) at the opposite sides to facilitate compact mixer assembly design. In order to use the same 2SB mixers for both polarizations we have added 90-degree waveguide twist.

The OMT for the Band 5 cartridge uses the core design of ALMA Band 4 [1] with redesigned output of one polarization; a 90-degree waveguide bend is added to place the OMT outputs at the opposite sides, Fig. 3. The measured OMT insertion loss at room temperature is less than 0.4 dB for both S12 and S13 over the entire RF band.

In order to fit the receiver components into the cartridge, we had to revise the originally proposed design for the Band 5 mixer as a scaled version of APEX Band 1 2SB SIS mixer [4] in favor of a more compact design. For the Band 5 mixer, we use MMIC style design of the SIS mixer with integrated on-chip LO injection and SIS junction capacitance integrated tuning circuitry. The mixer chip however has one DSB mixer [5, 6] in contrast to [4]. In order to use the same configuration 2SB mixer for both polarizations, we have added a 90-degree waveguide twist, Fig. 4.

|

|

Fig. 4. Band 5 mixer assembly. The assembly comprises the OMT, two 2SB mixers and corresponding IF chains (not shown) with the corrugated feed horn attached to OMT input port 1 (Fig.3).

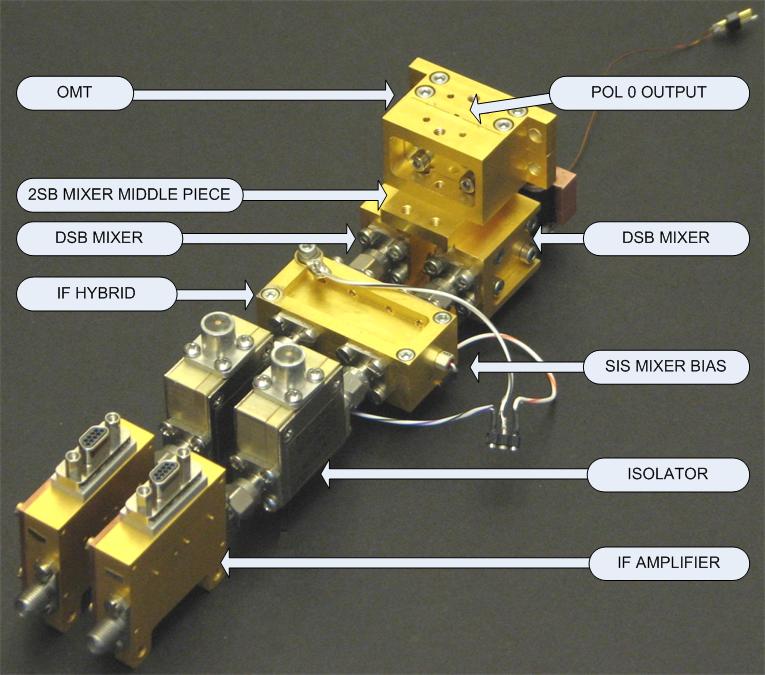

The mixer block has end-piece configuration with SIS mixer substrate having mirrored layout for different polarizations and being placed facing the RF and LO signals in the waveguides, with the IF outputs are directed towards the cartridge 300 K flange. Please visit a separate webpage for the ALMA Band 5 mixer development. Such design allows us to use the space between the mirror and the optics support brackets for placing the mixer assembly, all integrated around the OMT. Consequently, we use a specially designed IF hybrid to align the IF chains with the 2SB mixer IF outputs. Fig. 4 shows the mixer assembly, comprising, the OMT, two 2SB mixers and the IF chain integrated with the corrugated feed horn.

The main achieved result of this design is that the IF system streamlined along the vertical axis of the cartridge; it uses all the space between the 4 K and 15 K stages, which is the only possible technical solution accounting for the large size cold optics. Consequently, this relatively long IF chain is exposed to potentially harmful mechanical stress as a result of thermal contraction. The mechanical stress caused by thermal contraction of different materials was largely removed by introducing a titanium intermediate piece in the IF support bracket, an approach similar to the one used by ALMA Band 9 to secure tightening of the screws. The titanium contraction coefficient is the least as compared to aluminum and copper. In order to remove the stress, a simple equation should be solved equalizing thermal contraction of the aluminum optics supporting brackets with the combined contraction of the copper and titanium parts of the IF supporting bracket that provides rigid support for the IF chain.

The cold IF amplifiers [7] are 3 ‑ stage HEMT amplifiers with the first stage using InP HRL HEMT provided by ESO for ALMA Band 5 project and the two other stages using GaAs HEMT transistor MGFC 4419G with amplifier performance presented in Fig. 5. The amplifiers have been redesigned as part of APEX Project and were accommodated for ALMA Band 5 in order to facilitate integration of Band 5 cartridge IF chain.

|

|

|

Fig. 5. Band 5 IF amplifier performance: gain (left axis) and noise (right axis) at different bias voltages @12 K ambient temperature. Typical power dissipation of the amplifier is below 7 mW.

The IF hybrid, the amplifiers with CTH1365K25 type PAMTech isolators, all use matched SMA contacts allowing direct connection of the IF components to each other and the corresponding 2SB mixers, Fig. 6.

|

|

Fig. 6. Picture of the Band 5 cartridge mixer assembly for one polarization. The assembly comprises OMT, 2SB mixer, custom-made IF hybrid with integrated SIS mixer bias-Ts, isolators [8], and IF amplifiers.

INTEGRATED LO ASSEMBLY

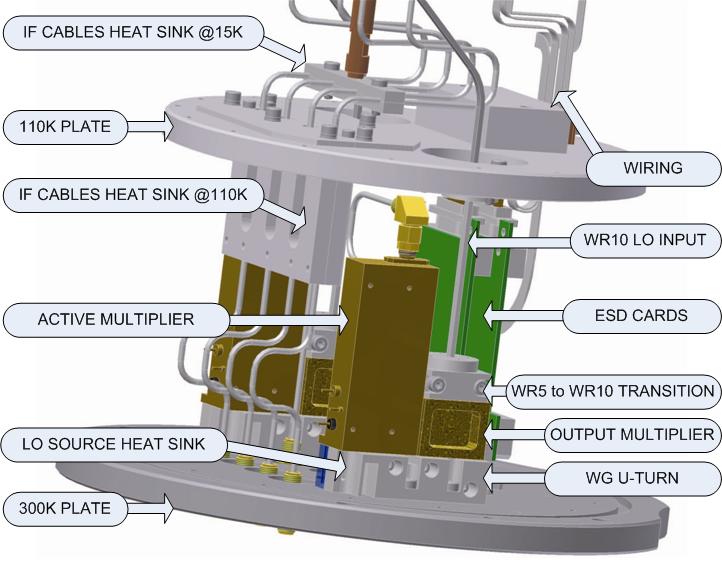

LO sources for Band 5 are developed by Rutherford Appleton Laboratory, UK. The suggested LO source layout comprises active tripler followed by a power amplifier and with final stage times two multiplier. This translates the required LO frequency band 171 – 203 GHz into input frequency band of 28.5 – 33.83 GHz. This relatively low input frequencies for the LO source allow us to use off-shelf vacuum bulk-head feed through K-type connector to avoid complexity of employing a custom-made waveguide LO interface between the WCA and CCA. However, this requires accommodation of the two LO sources inside the cartridge on 300 K plate at the vacuum side and installing an additional DC connector to bias active multipliers and power amplifiers. Fig. 7 shows the planned layout for integration of the LO sources on the 300 K plate of the Band 5 receiver cartridge.

|

|

Fig. 7. Band 5 cartridge integrated LO sources. The sources are combined in U-shape to improve cooling and extend the distance of the LO output to the 110 K plate. That reduces thermal load @110 K via LO output waveguide.

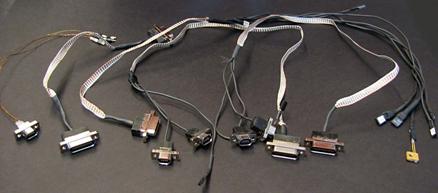

CARTRIDGE CABLING AND WIRING

The Band 5 receiver cartridge uses standard ALMA DC interface connector with ESD cards directly attached to it at the vacuum side at 300 K plate, Fig 7, 8. The wiring inside the cartridge is done using cryowires with 12 twisted pairs integrated into a loom [9]. Heat sinks for every temperature level are done similar to the design presented in [10]. The IF cables are shaped to relief stress caused by thermal contraction and to allow minimize the thermal load due to thermal conduction through the cables and wires and power dissipation, for wires. For more details, please see poster and report M. Strandberg et al. [11].

ESD cards employ protection circuitries similar to those used by ALMA Band 3. We have chosen to use dedicated wire bus for SIS mixer DC bias only and separate wire buses for DC biasing of IF amplifiers for each polarization; the forth wire bus carries magnetic field coil currents, defluxer and temperature sensor connections. This is done to reduce EMI for SIS DC bias and HEMTs. Necessary cross-connections are done between the two ESD cards.

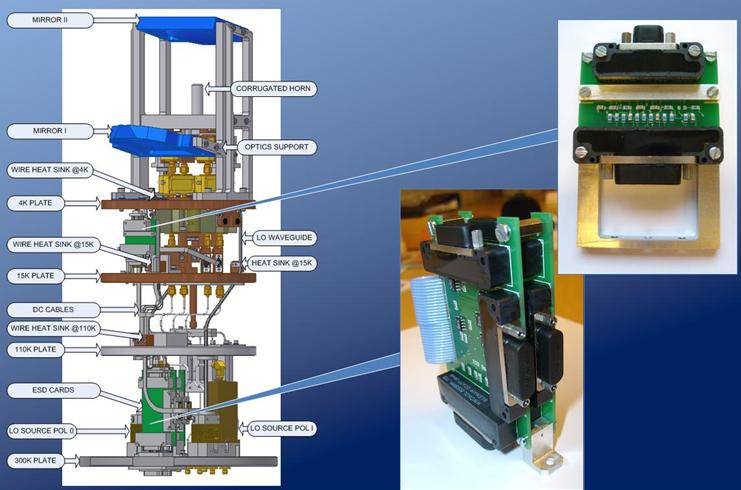

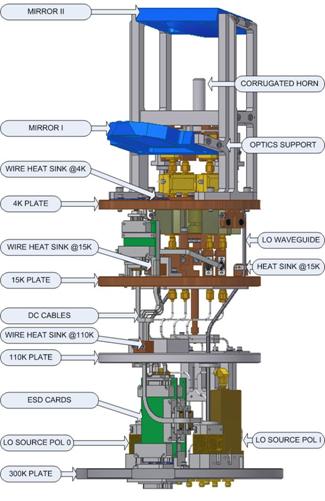

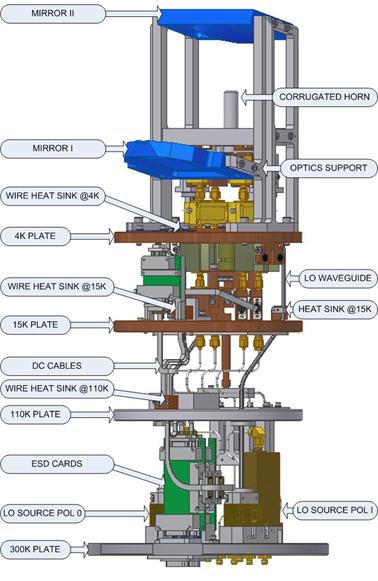

Finally, Fig. 8, 9 and 10 display a 3D model of the entire ALMA Band 5 cold cartridge assembly with removed fiberglass spacers between the temperature plates, for better visibility of the cartridge design and internal components and showing different hardware parts with its position inside the cartridge.

|

|

Fig. 8. Band 5 receiver cartridge cold assembly 3D model showing placement of internal components and with pictures of the ESD cards and SIS DC bias card.

|

|

|

|

|

Fig. 9. Band 5 receiver cartridge cold assembly 3D model. The fiberglass spacer between the cartridge plates have been removed for better visibility of the details and inner components. Pictures show the harnesses, cables and oversized waveguides used for LO transport inside the cartridge from the LO sources to SIS mixers.

|

|

|

Fig. 10. Band 5 receiver cartridge cold assembly 3D model and integrated Band5 cartridge prototype side-by-side.

Currently, ALMA the Band 5 receiver cartridge is in the final integration stage and we expect an extensive test program to be started shortly. The cartridge tests include room temperature optics characterization, based on Agilent vector network analyzer with frequency extension for direct vector measurements in the band 160 – 220 GHz. The cartridge test cryostat [12] has been integrated with Y-factor measurement system, sideband rejection characterization setup and cartridge cold beam measurement hardware similar to [13]. In order to eliminate effects of atmospheric water on the measured data, the measurement equipment is enclosed into a plastic cabinet purged with dry Nitrogen.

CARTRIDGE PERFORMANCE

The ALMA Band 5 prototype receiver cartridge had been extensively tested and the results of the final tests were presented in the test report document which is posted on ALMA EDM server. Here we present some of the relevant performance information.

|

|

|

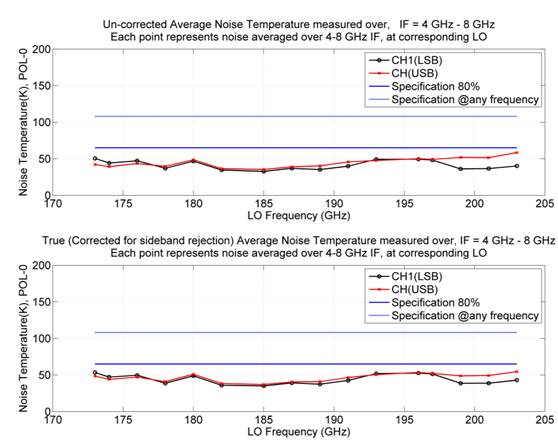

Figure 11. Averaged over IF (4-8 GHz) noise temperature vs. LO frequency. Polarization 0. See also the legend in the plots. |

|

|

|

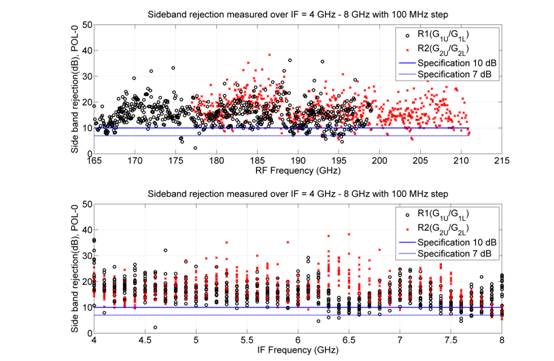

Figure 12. Measured sideband rejection vs. RF and IF frequency for LO frequencies from 172 to 203 GHz with 2 GHz step. Polarization 0. See also the legend in the plots. |

|

|

|

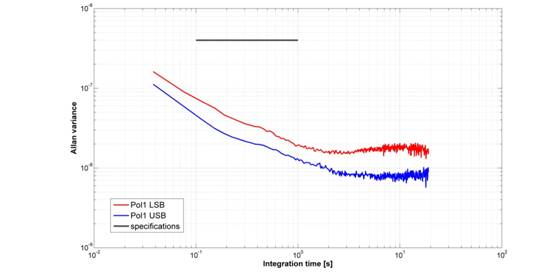

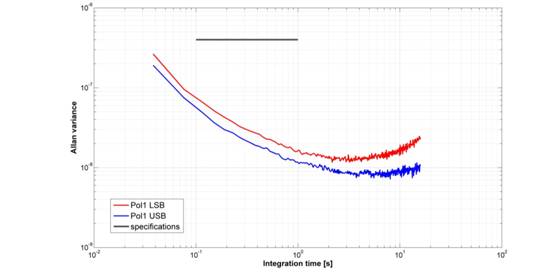

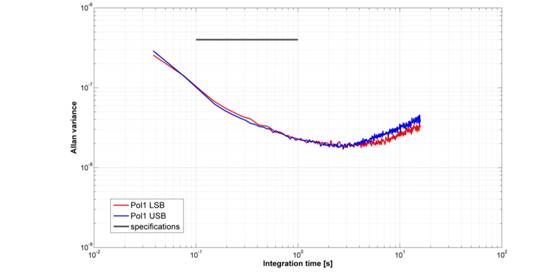

Figure 13. Allan variance based on measured data (Pol.1, USB, LSB) at the LO frequency 172, 182, 202 GHz (top, middle, bottom), measurements of power was performed over the IF band 4-8 GHz. |

CONCLUSION

We presented details on the design of ALMA Band 5 prototype receiver cartridge and some data on performance of its components. Detailed information on 2SB mixer design and its performance is presented in [6]. We successfully solved problems of integration of the dual polarization 2SB receiver into the cartridge whereas keeping required cold mirror rim size of the 5wo. ALMA Band 5 Cold Cartridge Assembly has passed the Critical Design Review (CDR) and in the near future six Band 5 receiver units will be produced, installed and commissioned.

References

[1] Band 5 OMT is slightly modified design suggested by Dr. S. Asayama for Band 5 and based on the ALMA Band 4 cartridge OMT.

[2] M. Carter, et al., “ALMA Front-end Optics Design Report”, FEND-40.02.00.00-035-B-REP, available from ALMA Project documentation server.

[3] M. Whale, N. Trappe, I. Lapkin, V. Belitsky, “Physical Optics Analysis of the ALMA Band 5 Front End Optics”, Proceedings of the 19th International Symposium on Space Terahertz Technology, pp. 368 – 372, Groningen, April 28-30, 2008.

[4] V. Vassilev, D. Henke, I. Lapkin, O. Nyström, R. Monje, A. Pavolotsky, V. Belitsky, "Design and Characterization of a 211-275 GHz Sideband Separating Mixer for the APEX Telescope", IEEE Microwave and Wireless Components Letters, pp.55-60, Vol. 18, Number 1, January 2008.

[5] B. Billade, I. Lapkin, R. Monje, A. Pavolotsky, V. Vassilev, J. Kooi, and V. Belitsky, “ALMA Band 5 (163-211 GHz) Sideband Separating Mixer Design”, Proceedings of the 19th International Symposium on Space Terahertz Technology, pp. 250-252, Groningen, April 28-30, 2008..

[6] B. Billade, I. Lapkin, A. Pavolotsky, J. Kooi, and V. Belitsky, “ALMA Band 5 (163-211 GHz) Sideband Separating Mixer”, to be presented at the 20th International Symposium on Space Terahertz Technology, Charlottesville, April 20-23, 2009.

[7] E. Sundin, “Development of Cryogenic Low Noise 4 – 8 GHz HEMT Amplifier and its Advanced Characterization,” Thesis for Licentiate in Electrical Engineering, Technical report No. 2006:9L, Chalmers University of Technology, 2006.

[8] Isolator CTH1365K25, PAMTECH Inc., 4053 Calle Tesoro, Camarillo, CA, USA.

[9] ICE Oxford Ltd., Unit 3, Ferry Mills, Osney Mead, Oxford, OX2 0ES, UK.

[10] D. Koller, J. Effland, A. R. Kerr, K. Crady and F. Johnson, “Miniature, Modular Heat Sinks for ALMA Cryostats”, ALMA MEMO #437, 2002. Available: http://www.alma.nrao.edu/memos/html-memos/abstracts/abs437.html .

[11] M. Strandberg, I. Lapkin, V. Belitsky, A. Pavolotsky and S.-E. Ferm, ”Analysis, Simulation and Design of Cryogenic Systems for ALMA Band 5 Prototype Cartridge”, to be presented at the 20th International Symposium on Space Terahertz Technology, Charlottesville, April 20-23, 2009.

[12] Y. Sekimoto, T. Kamba, S. Yokogawa, M. Sugimoto, T. Okuda, R. Kandori, K. Tatematsu, K. Muraoka, A. Ueda, T. Nishino, N. Okada, T. Fukuda, K. Kaneko, H. Ogawa, K. Kimura, K. Noda, K. Narasaki, and K. Suzuki, “Cartridge Test Cryostats for ALMA Front End”, ALMA MEMO #455, 2003. Available: http://www.alma.nrao.edu/memos/html-memos/abstracts/abs455.html.

[13] O. Nyström, I. Lapkin, V. Desmaris, D. Dochev, S.-E. Ferm, M. Fredrixon, D. Henke, D. Meledin, R. Monje, M. Strandberg, E. Sundin, V. Vassilev, and V. Belitsky, ”Optics Design and Verification for the APEX Swedish Heterodyne Facility Instrument (SHeFI)”, to be published in Int. Journal Infrared and Millimeter Waves, June, 2009.

Contacts:

Visit GARD web-page http://www.chalmers.se/rss/EN/research/research-groups/advanced-receiver & http://gard04.rss.chalmers.se/ .

Site maintained by Magnus Strandberg